Conquering Overproduction: Harnessing Takt Time for Efficiency

Overproduction: Your Silent Enemy in Efficiency

Have you ever found yourself knee-deep in excess stock, wondering why you have more goods than you know what to do with? Overproduction is like that friend who always invites themselves to your dinner party—unwanted and a bit awkward. If you want to be more efficient and keep your resources aligned with your actual needs, it’s time to face this silent enemy head-on.

Why Overproduction is a Problem

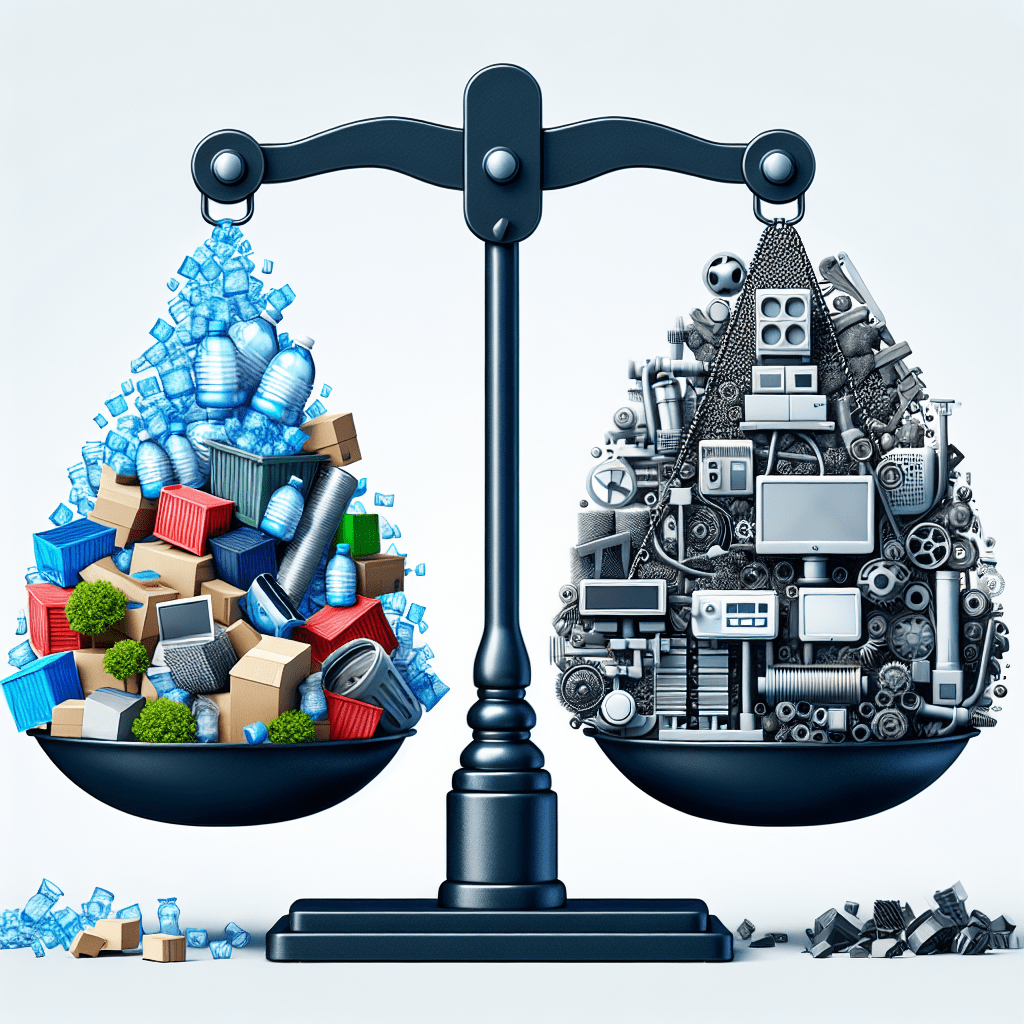

Overproduction isn’t just about the piles of unsold products. It goes deeper than that. When you produce more than necessary, you’re not only wasting precious resources but also jeopardising your overall efficiency. Imagine pouring your heart and soul into a project only to find out nobody needed it. Frustrating, isn’t it?

By understanding the dynamics of overproduction, you open the door to better decision-making. It’s about more than just numbers; it’s about aligning what you create with what your customers actually want. And that’s where Takt Time comes into play.

What is Takt Time and Why Does it Matter?

Takt Time is essentially the heartbeat of production. It’s that rhythm that keeps your workflow in sync with customer demand. The term might sound a bit technical, but don’t let it scare you off. When calculated correctly, Takt Time will help ensure that you’re producing just enough—nothing more, nothing less.

Think of it like this: if you know how much your customers need and when they need it, you can streamline your production process. This means fewer resources wasted, less time spent on unnecessary tasks, and a better overall output. What’s not to like?

Three Key Benefits of Calculating Takt Time

So, why should you invest time in calculating Takt Time? Here are three compelling reasons that will have you rethinking your production strategy:

- Clarifies Production Goals: Takt Time provides a clear target for your team, so everyone knows what needs to be done and when. No more guesswork or confusion.

- Identifies Bottlenecks: By establishing Takt Time, you’ll quickly spot where things are slowing down. This makes it easier to address issues before they balloon into major problems.

- Balances Workloads: It helps distribute work evenly across your team. No more frantic last-minute rushes, just a steady flow of productivity.

Getting these elements right can transform your approach and create a culture of efficiency. It’s not just about numbers on a spreadsheet; it’s about making tangible improvements in your day-to-day operations.

How to Embrace Takt Time in Your Process

We’ve established the what and why, but how do you actually embrace Takt Time in your workflow? Start simple. Measure how long it takes to produce a single unit, then divide that by customer demand within the same timeframe. Voila! You have your Takt Time.

As you get comfortable with this concept, make it a team effort. Encourage open discussions where everyone can contribute ideas on improving efficiency. The best insights often come from those on the front lines.

When I first applied Takt Time in my team, the transformation was nothing short of remarkable. We not only improved our output but created a more engaged atmosphere where everyone felt part of the solution. It’s about fostering a sense of ownership over what we do.

The Takeaway: Align with Your Customers’ Needs

Ultimately, embracing Takt Time does more than just improve productivity. It reshapes your entire approach to production. So, I encourage you to ask yourself: what steps are you taking to ensure your production aligns with customer needs?

Overproduction may be a silent enemy, but with the right tools and mindset, you can turn it into your greatest ally. Take a moment to reflect on your current processes and consider how Takt Time might help you streamline your operations.

Together, let’s keep our production aligned with what truly matters—our customers.

Now tell me, what changes are you thinking of implementing to combat overproduction?