Steering Towards Success: The Importance of Quality in Business Processes

Are You Driving Your Business Off a Cliff?

Let’s face it: if you’re not stopping to evaluate your processes, you might be steering your business straight towards disaster. It sounds dramatic, but it’s true. In a world that demands speed and efficiency, taking a moment to assess how we do things can feel counterintuitive. Yet, it’s crucial for sustainable success.

The Value of a Mindset Shift

At City Skills, we champion the idea that quality isn’t merely a box to tick off on a checklist; it’s a way of life. The essence of Toyota’s approach emphasises a culture where stopping to identify problems is not just tolerated but celebrated. Why is this so important? Let’s delve into three vital reasons why embracing this principle can transform your business.

1. Empowering Your Team

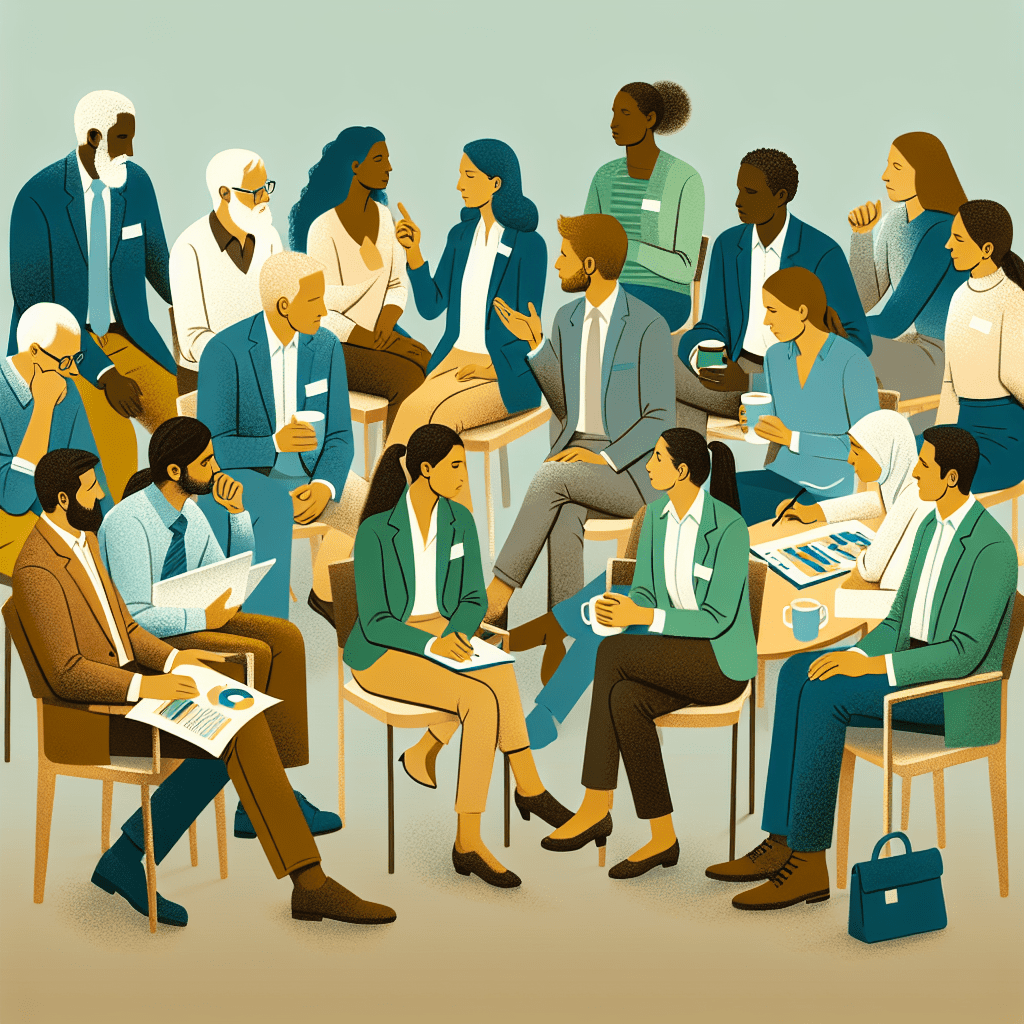

First up, when team members feel safe to voice their concerns, it creates an environment of engagement and collaboration. Imagine a workplace where no one hesitates to speak up about a potential issue. Everyone feels like they have a stake in the operation, which leads to a more motivated workforce. After all, when people care, they contribute, and that’s where the magic happens.

Moreover, this culture of openness allows for more diverse perspectives. Different viewpoints can spark innovative solutions. When was the last time a member of your team brought a fresh idea that made you rethink your approach? Engaging your team in this way not only boosts morale, but it also enhances creativity, driving your business forward.

2. Preventing Costly Mistakes

Next, let’s talk about money. Early identification of “out-of-standard” conditions enables you to catch problems before they escalate. Preventing costly mistakes isn’t just about saving cash; it’s about safeguarding your reputation. The last thing you want is a mistake to blow up into a crisis.

Think about it: how many times have you seen a small issue snowball into a major problem? By fostering an environment where concerns can be addressed promptly, you’ll reduce the risk of crisis management headaches later. This proactive approach not only enhances operational efficiency but also instils confidence among clients and stakeholders.

3. Building Long-Term Quality

Finally, focusing on quality today lays the groundwork for stronger operations in the future. It’s a bit like planting a seed. The efforts you invest now in refining your processes will yield positive results down the line. Quality should be baked into your operations rather than something you layer on top when problems surface. This commitment to excellence will resonate with clients and set you apart from your competitors.

I remember a time in my early career when I was so busy trying to meet quotas that I overlooked the finer details. It wasn’t until a key client pointed out a significant oversight that I realised the importance of quality assurance. That moment was a turning point for me. It taught me that taking time to reflect on processes isn’t a luxury; it’s a necessity. It’s a lesson I carry with me every day.

How About You?

So, how often do you pause to reflect on your processes and make necessary adjustments? Are you guilty of speeding past potential pitfalls? Taking the time to evaluate and improve isn’t about slowing down; it’s about accelerating your success.

In a rapidly changing landscape, adopting a culture of continuous improvement will not only bolster your team’s morale but also drive long-term business success. So, let’s start the conversation. What changes can you make today to foster a mindset of quality and improvement within your organisation?

If you’ve enjoyed this discussion, I encourage you to reflect on your own practices. Remember, it’s not just about keeping the wheels turning; it’s about making sure they’re aligned for the road ahead.

#CitySkills #QualityControl #ContinuousImprovement