Breaking the Cycle of Quality Issues with the Fishbone Diagram

Are You Tired of Getting the Same Quality Issues? It’s Time to Dig Deeper

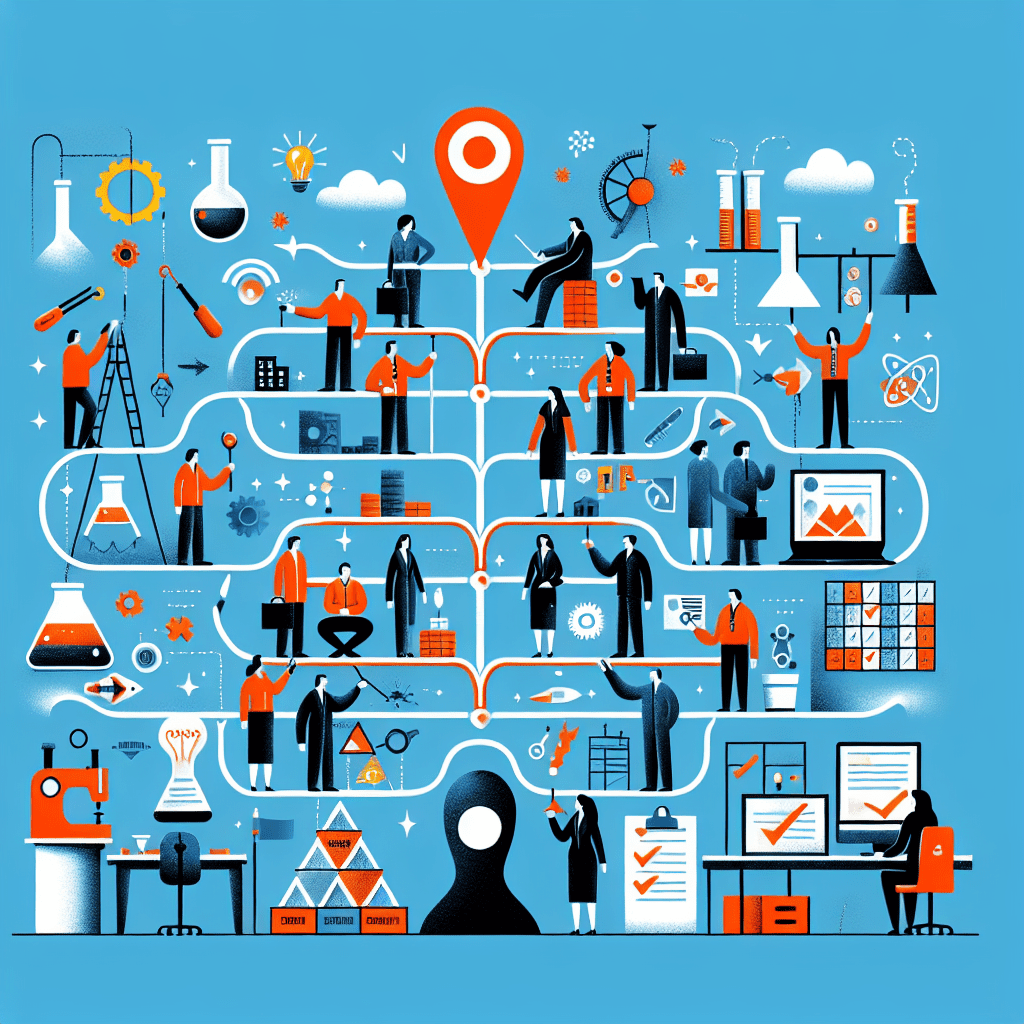

Let’s face it, we all dread facing the same quality problems repeatedly. It can feel as if we’re stuck on a merry-go-round, chasing our tails. But what if I told you there’s a way to break that cycle? Yes, I’m talking about the Fishbone Diagram, also known as the Cause-and-Effect or Ishikawa Diagram. This straightforward tool could be your golden ticket to understanding and solving persistent issues.

What is the Fishbone Diagram?

The Fishbone Diagram helps teams uncover the real root causes of problems by categorising them into six key areas: Man, Method, Machine, Material, Measurement, and Environment. Think of it as a visual map for clarity, guiding you through a world of vague concerns to specific, actionable insights.

You might be wondering why this is important. The world thrives on efficiency. Whether you’re fine-tuning a production line, aiming for improved employee engagement, or addressing critical customer feedback, the Fishbone Diagram is an essential addition to your problem-solving toolkit.

Transforming Conversations

One of the standout features of the Fishbone Diagram is its ability to convert vague worries into clear conversations. Instead of vague complaints fluttering around a meeting room, you’ll find a structured approach that encourages everyone to get involved. Who doesn’t love a good brainstorming session where everyone’s thoughts matter?

During our workshops at City Skills, I’ve seen teams light up as they delve into the “why-why” approach. This method prompts individuals to ask deeper questions that peel back the layers of complexity surrounding an issue. It’s invigorating to watch teams go from confusion to synergy as they uncover hidden problems.

Revealing Hidden Problems

One of the beautiful things about the Fishbone Diagram is its knack for revealing the unexpected. Often, the root of an issue isn’t where you think it is. It could be a small oversight that, when addressed, leads to those “aha” moments we all crave. There’s something so satisfying about connecting the dots and realising that a complex problem can have a straightforward solution.

In my experience, this tool has led to remarkable changes in various sectors—quality assurance, cost management, delivery logistics, safety protocols, and even improving staff morale. The adaptability of the Fishbone Diagram makes it truly invaluable. And let’s face it, who doesn’t like a tool that can wear multiple hats?

Don’t Stop at Symptoms

Remember, don’t stop at identifying symptoms. Keep asking why until you strike gold. And by gold, I mean not just tackling a few surface issues, but getting to the core of what’s really happening. Repeatedly asking “why” helps you to dig deeper, illuminating issues that may have been lurking beneath the surface. This deep dive can be the key to significant improvements.

In my own journey, I once faced a frustrating quality issue with a ship’s component. Instead of tackling just the apparent malfunction, we rallied the team and went through a thorough Fishbone analysis. The realisation that a minor error in material sourcing was the root cause transformed our approach and saved us time and money.

Your Strategy for Success

So, what’s your favourite strategy for getting to the heart of an issue? Whether you’ve been using the Fishbone Diagram or have your own go-to method, I’d love to hear your stories. Let’s share insights and continue to refine our approaches.

Are you ready to take action? Don’t just sit idle with recurring quality problems. Grab that Fishbone Diagram and get your team involved. You may be surprised at what you uncover.

After all, problem-solving is a journey, not a destination. What will you discover on yours?